As you are probably aware, oil doesn't grow on trees.

The world uses millions of barrels of the stuff each and every day to keep everything ticking along nicely, but extracting the stuff from the vast underground reservoirs isn't exactly a simple task.

Engineers have got even more on their plate when they're trying to draw the viscous liquid out from underneath the ocean floor, rather than land.

Advert

It's an extremely delicate dance to get one of those mammoth megastructures you see in the ocean - known as offshore oil rigs - up and running, as they are pretty much immense floating islands.

There's plenty dotted about too, including in the North Sea, the Baltic Sea and the Arctic Ocean, to name a few.

But how on earth do these gigantic hunks of metal get out into the ocean?

Advert

Well, after taking three to five years to build due to the complexity of the framework, they are dragged out to sea on enormous ships so that they can reach oil reserves which are unreachable from land.

There are a range of different types of offshore oil rigs which are each specifically engineered to deal with the conditions and depths they will face - but fixed platforms are arguably the most bonkers ones that are floating out there.

Fixed platforms

These are one of the most common type of offshore oil rigs and just as the name suggests, they are literally 'fixed' to the seabed to suck up it's oil.

Advert

YouTuber Jasper Storm, who dubs himself the 'Master of Engineering', explained that this is no easy feat, seen as though the deepest point of the ocean ever recorded by humans is a whopping 6.8miles below the surface.

In a video discussing the topic, he explained: "If you put Mount Everest upside down in the ocean, there would still be over a mile before you get to the bottom.

"So how is it possible to build these megastructures in the midst of all this? Where waves can be as tall as ten-storey building? Some people even jokingly say that they build the oil rigs first and then build the ocean around them."

Advert

But obviously, that isn't the case.

Jasper continued: "You see, in shallow waters, fixed steel structures are installed in the ocean floor.

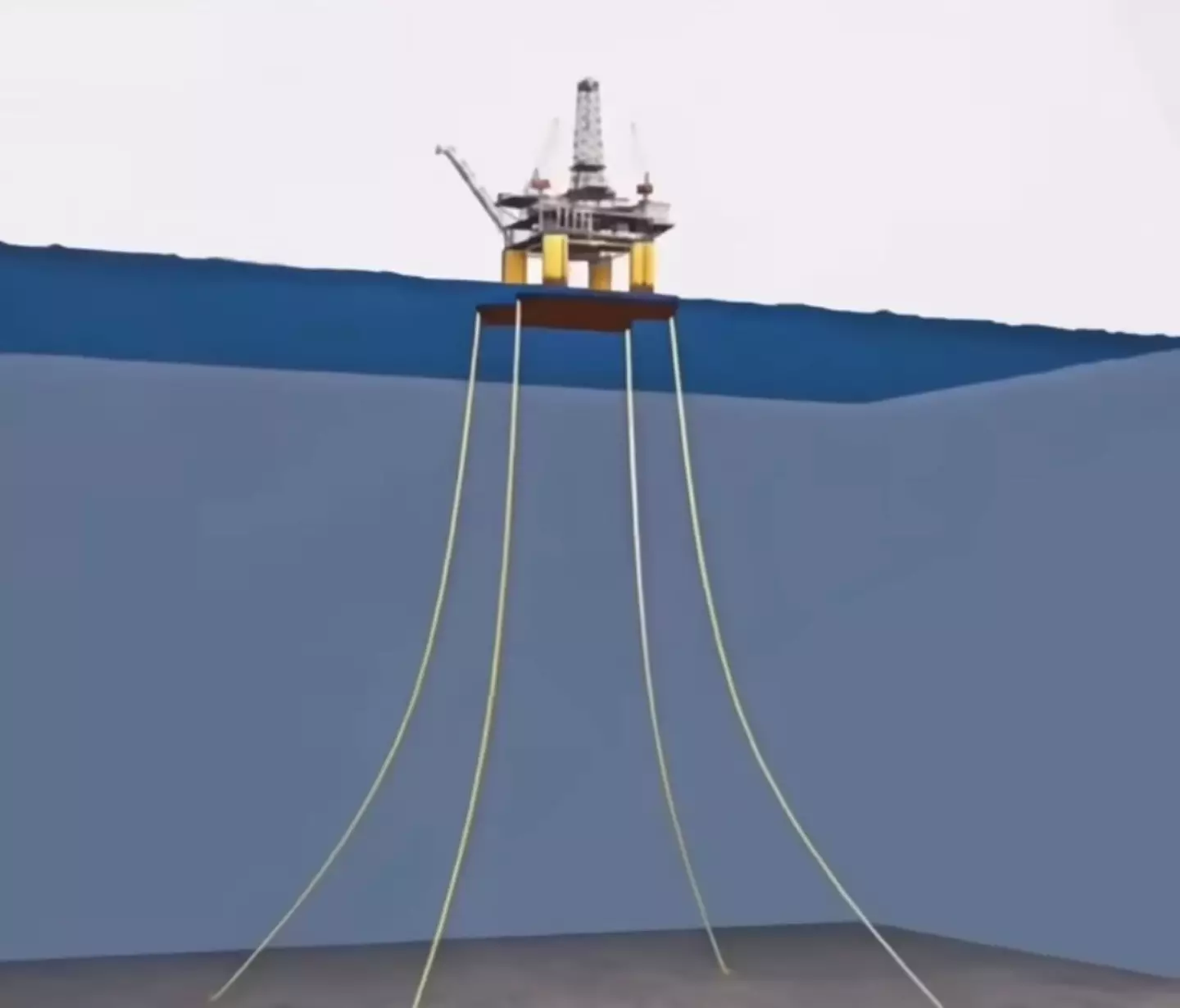

"But for the deeper waters, floating platforms are used that are anchored securely to the ocean floor."

How they work

This complicated process involves using lengthy steel-reinforced concrete legs which are driven deep into the seabed and anchored there to support the working deck which sits above the water.

Advert

The main advantage of this type of oil rig is that it is a lot more stable than it's peers and can withstand powerful wind and rain due to being attached to the ocean floor.

Fixed platforms are suitable for depths of up to around 520m, as it is simply not economical to build legs long enough to reach the bottom in extremely deep water.

Semi-submersible platforms are a better fit for this gig, as they have brilliant buoyancy which allows it to float above the drill site.

They can be moved from place to place by simply letting air in or out of the lower hull, while huge anchors give them some stability.

Semi-submersible oil rig platforms can be used to drill in deep water, of depths of up to 6,000m.

People were left stunned after finding out what goes on behind-the-scenes in the offshore oil rig world.

One said: "The engineering of such platforms is astonishing," as another wrote: "Mad respect for all who construct these massive structures! Speechless!"

A third added: "I never knew I could get even more scared of being on a deep sea oil rig. Thank you."

While a fourth chimed in: "Anyone brave enough to take on Poseidon has my deepest respects."

You can say that again.

Topics: Science, World News, Weird